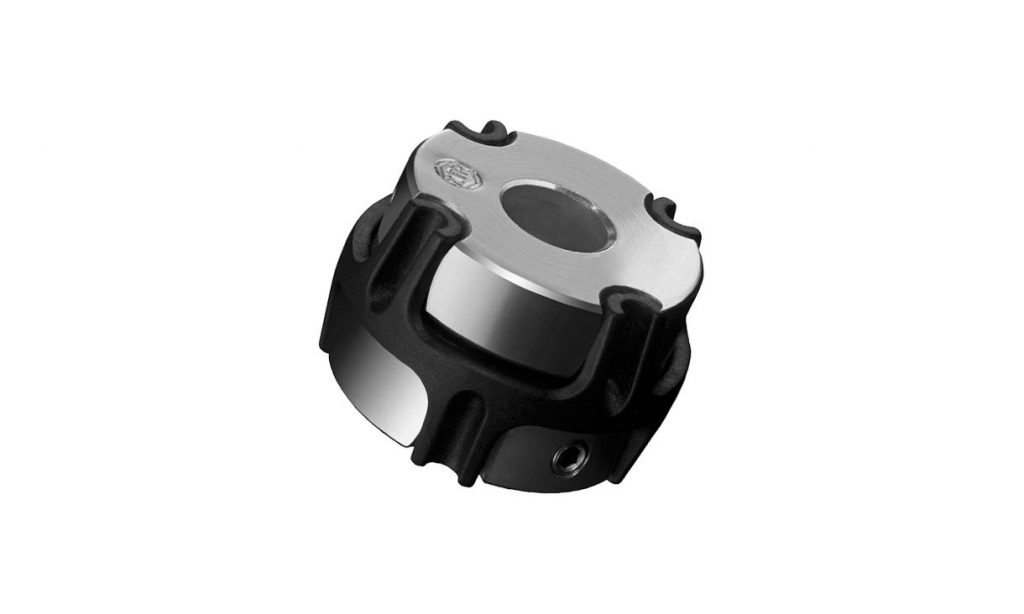

Servo couplings

The couplings offered here ensure a free of play transmission of torque and are able to compensate any shaft misalignments. They are available in single-piece and multi-piece versions. Therefore they can be selected individually according to the area of application and requirements.

How do servo couplings work?

The axially true and low-loss torque transmission of servo couplings is produced by a high torsional stiffness and a low mass moment of inertia. The primary goal is to bridge the shaft misalignment between the driven shaft and the shaft to be driven, thereby preventing interference. The following various designs can compensate for this misalignment as well as serve as torque limiters to protect the equipment and provide various advantages.